Location: Home > News > Company news

On March 25, 2020, Suzhou New HongJi Precision Parts Co., Ltd (New HongJi) formally established a strategic partnership with Shanghai Fastems (Finfar Automation), signed an agreement for the purchase and implementation of high-end customized FMS production line. New HongJi began to prepare for smart manufacturing in early 19, optimizing and improving machining operations, production line New HongJi started to prepare for intelligent manufacturing in early 19, optimizing and improving machining operations, deep integration of production lines, and expansion of intelligent factories are our future steps. The high-end flexible production line lays the foundation for New HongJi to accelerate the realization of intelligent manufacturing, and also sets up an industry benchmark for flexible manufacturing in the machining field!

Mr. Li signed a contract with Fastems Shanghai

New HongJi was founded with the business philosophy of multi-species, small batch, and has accumulated more than twenty years of production experience in producing precision parts, with strong technical force and excellent engineering craftsmanship and mechanical manufacturing capabilities. Innovation is our soul, high efficiency is our tenet, we strive to pursue the realization of planning automation, transmission automation and monitoring automation, the helmsman, General Manager Li Jian, has a clearer understanding of intelligent manufacturing than the same industry, where is the way out of traditional machining? How to make the enterprise sustainable? He said automation development is the only way out, and continuous optimization of management is the key.

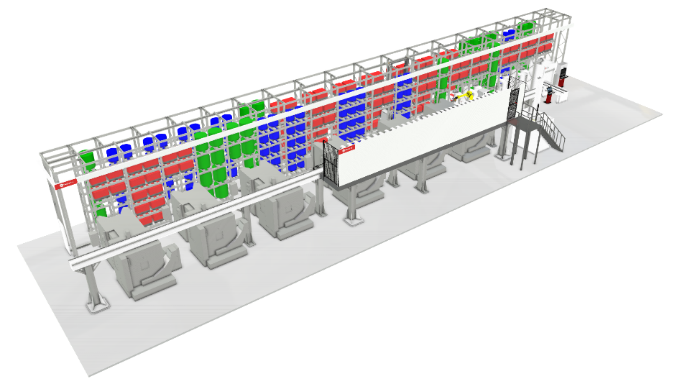

High-end customized FMS production line

FMS production line, integrated by 4-axis horizontal machining centers and 5-axis machining centers, hundreds of material pallets and machined pallets, with ultra-high and extra-large magazine capacity and high efficiency stacker cranes, and loaded with MMS software, all the pallets, fixtures, and materials/blanks and WIPs will be centrally stored in three-dimensional magazines, and automatically transported to the loading station. The design of the central tool magazine is the biggest highlight of the production line. The central tool magazine is built above the machine tool, which does not occupy any floor space at all, and achieves zero error in tool management through the automatic transfer of the robot and the real-time management and monitoring of the automation software. Our goal is to solve the fundamental downtime problem of the machine tool through the integration of the central tool magazine of the flexible line, and to increase the machining efficiency of the machine tool to more than 92%. The central tool library not only improves efficiency and reduces errors, but also realizes tool sharing, reduces the use of sister knives, and tool life management can be optimized, so-called one-two punch! After the completion of the FMS production line, it will reduce the dependence on manual labor, and it will reduce the risk of manual errors, and we will realize the state of 24-hour unattended, dozens of products produced at the same time, and realize the maximization of efficiency!

Central tool storage

Delivering the quality of Made-in-China, enhancing the reputation of Made-in-China, and realizing the Chinese dream of the great rejuvenation of the Chinese nation! This is our mission; to be a world-class innovative manufacturing enterprise, to realize the highest per capita contribution per unit, the highest per capita income per employee, and the highest return to shareholders in the same industry, is our vision. new HongJi has always been a forward-thinking, international vision, and is an innovative enterprise with full of vigor. 2020, in the wave of intelligent manufacturing, new HongJi will make great efforts to introduce high-end flexible production lines. In 2020, under the wave of intelligent manufacturing, New HongJi will make efforts to introduce high-end flexible production lines, and the management and international operation ability and level will be further improved. In the near future, we will complete the construction of two production lines, and further accelerate the pace of intelligent manufacturing through process reengineering, we are committed to exploring a transformation and upgrading road suitable for the development of China's manufacturing enterprises, and help accelerate the process of China's intelligent manufacturing!