Location: Home > News > Company news

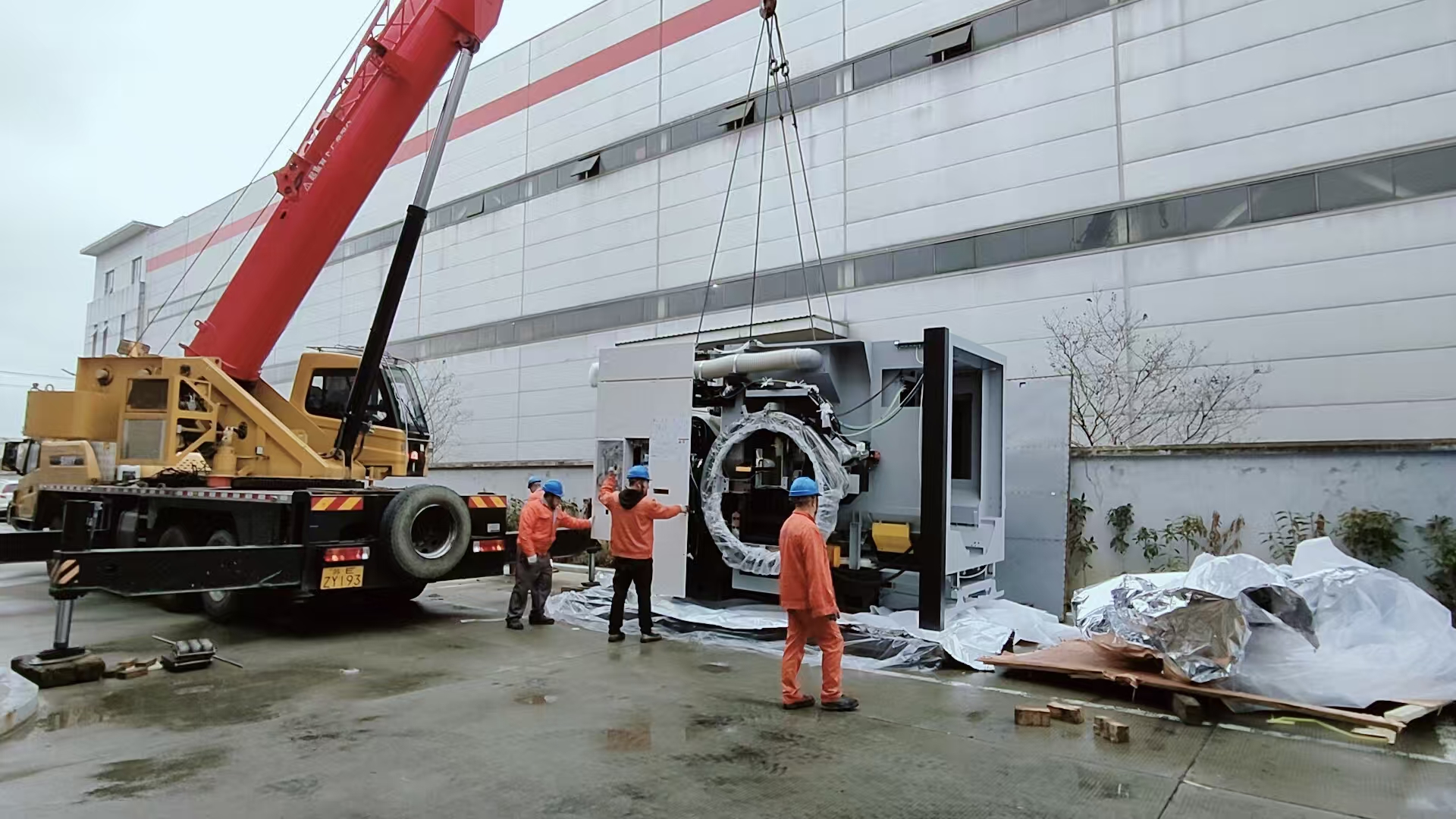

Recently, New HongJi has taken another crucial step in the field of precision machining by successfully ordering the latest DA500 model developed by Makino. This equipment is equipped with 120 cutting tools and will be dedicated to serving customers in the semiconductor industry, mainly used for the production and machining of ultra-high precision parts. The introduction of this equipment demonstrates the company's firm strategy of continuous deepening and investment in the technical field.

Semiconductor manufacturing is a typical field where "precision is of utmost importance". Ultra-precision parts, as the core components of semiconductor equipment, require extremely high machining precision. Any slight defect may have a significant impact on the quality and performance of semiconductor products. Our company is committed to providing high-quality machining services for the global semiconductor industry. The introduction of the DA500 model this time is precisely to better meet the stringent requirements for precision in the industry.

As a five-axis vertical machining center for component machining, the Makino DA500 has many excellent performances. It helps the company to better meet the machining requirements for complex three-dimensional shapes and smooth curved shapes in the machining of components for semiconductor manufacturing equipment, aerospace, medical and other industrial equipment, and ensures high machining surface quality. Its large-capacity configuration of 120 cutting tools can reduce the number of tool changes, greatly improving machining efficiency and precision, and is especially suitable for multi-process machining of precision parts in the semiconductor industry.

In order to better serve customers, we always pay attention to cutting-edge technologies in the industry and customer needs. The continuously rising requirements for precision machining in the semiconductor industry have prompted us to continuously invest in advanced equipment and technologies. The introduction of the DA500 can not only enhance our machining capabilities but also represents an important measure for us to deepen our layout in the semiconductor industry. We will take this opportunity to further optimize the process flow and provide customers with higher-quality and more efficient services.

We have always spared no effort in technical investment. The introduction of the DA500 this time is just a microcosm of the company's long-term technical strategy. Over the years, the company has continuously increased its investment in precision machining and inspection equipment, and has been constantly developing new machining processes and technologies to meet the stringent requirements of the market for the efficiency, precision and cost of machine tools.

With the vigorous development of the semiconductor industry, the demand for precision machining is also continuously growing. By virtue of this equipment upgrade and technical investment, we will occupy a more favorable position in the highly competitive market, provide more reliable and higher-quality ultra-precision part machining services for customers in the semiconductor industry, and achieve our own continuous progress.