Location: Home > News > Company news

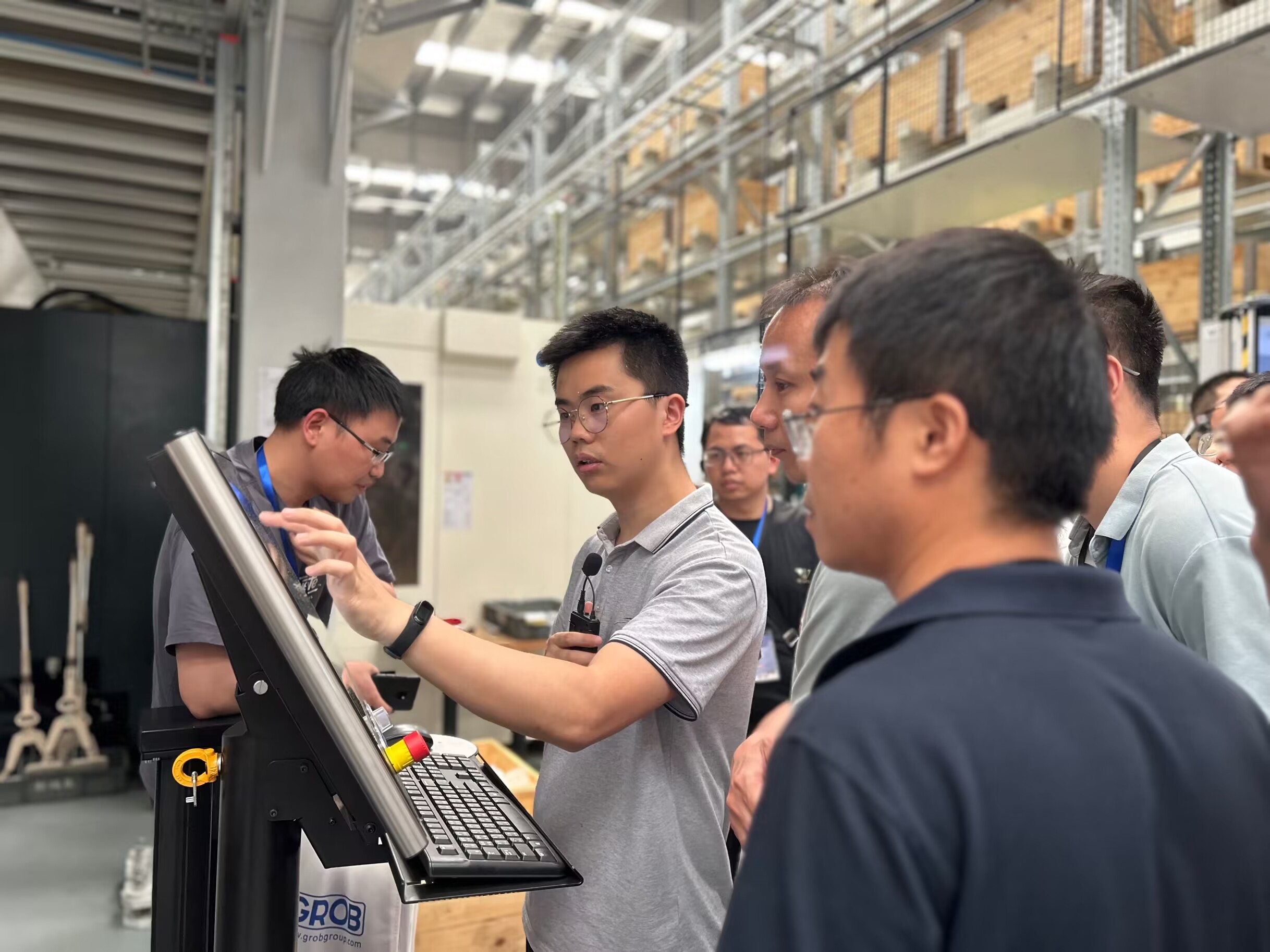

From June 7 to 9, the "2023 Intelligent Manufacturing New Technology Conference (MICA)" was organized, gathering over 70 professionals in intelligent manufacturing from AVIC, AECC, CASIC, and CASC enterprises. On June 8, they visited the production site of New Hongji in Suzhou.

The concept of "flexible production" has been around for decades, emerging from the need to address rapidly changing market demands and intense competition. Compared to rigid production, flexible production offers greater adaptability and quicker response times to order changes, making it ideal for "high-mix, low-volume" discrete manufacturing. Since its inception, New Hongji has adhered to this high-mix, low-volume business philosophy for 30 years, continuously innovating in management and technology to maintain its leading position in the high-precision manufacturing field.

New Hongji has now embarked on the digital transformation of its factory. By leveraging intelligent manufacturing and flexible production lines to their fullest, the company aims to achieve high efficiency, high productivity, and high quality in production, ensuring its leadership in the specialized machinery manufacturing market.

In terms of management, New Hongji follows a development path of "standardization, digitalization, automation, and intelligence." The company has steadily grown and accumulated expertise, ensuring that once its digital network is fully established, the transition to automation will be seamless.

In his speech, General Manager Li Jian discussed the company's strategy, tactics, and operational effectiveness. He generously shared his experiences and insights from the exploration, planning, and eventual establishment of the flexible production line over the past couple of years. Li’s sincere sharing received high praise and unanimous approval from the visiting customers. The advantages of automation are evident; however, it is the integration of a company's strategy, management, and production with automation that leaves a lasting impression and provokes deep thought.

On the day of the visit, our Manufacturing Department Technical Supervisor, Wang Lei, introduced the implementation and operation of "flexible automation" to the visitors. As a successful user of Fastems flexible automation, New Hongji boasts the first flexible production line in China integrated with a central tool library by Fastems. The implementation of this flexible line occurred in two phases: the first phase integrated two five-axis machining centers and one horizontal machining center with over 100 machining pallets and 100 material pallets, successfully doubling the overall equipment effectiveness (OEE). The second phase, completed in August 2022, added three more machines to the original line, achieving full integration of four five-axis machining centers and two horizontal machining centers. The entire line was also equipped with a central tool library housing 1,024 tools, which will continue to support increased production efficiency.

New Hongji aims to provide global customers with component solutions in the medical, optical, general industrial, semiconductor, and aerospace fields. As a machining manufacturing enterprise, New Hongji has amassed 30 years of rich experience in high-precision manufacturing, successfully delivering nearly three million parts annually across Europe, North America, and Asia.

With the maturing application of intelligent flexible production lines in manufacturing, coupled with New Hongji’s professional service team, the company will continue to safeguard the path of "high-mix, low-volume" production, ensuring excellence in high-precision component manufacturing.