Location: Home > News > Company news

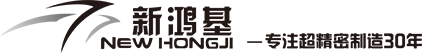

On the morning of October 24, 2024, at 9:00 a.m., the presentation team from the Finnish Fastems China subsidiary led entrepreneurs from the Zhejiang Pump Industry Association on a visit to New Hongji. The purpose of this event was to deepen understanding of fully automated production lines and promote technological exchange and collaboration among industry enterprises.

During the tour, the Fastems team first guided the entrepreneurs through New Hongji’s fully automated production line equipped with Fastems technology. Through a detailed introduction, the entrepreneurs learned how the Fastems system addresses multiple challenges in the machining industry, such as recruitment difficulties, rapid technological upgrades, and fierce market competition, by introducing intelligent manufacturing systems and equipment. These challenges are alleviated through digital transformation and the adoption of automation systems, significantly improving production efficiency and product quality.

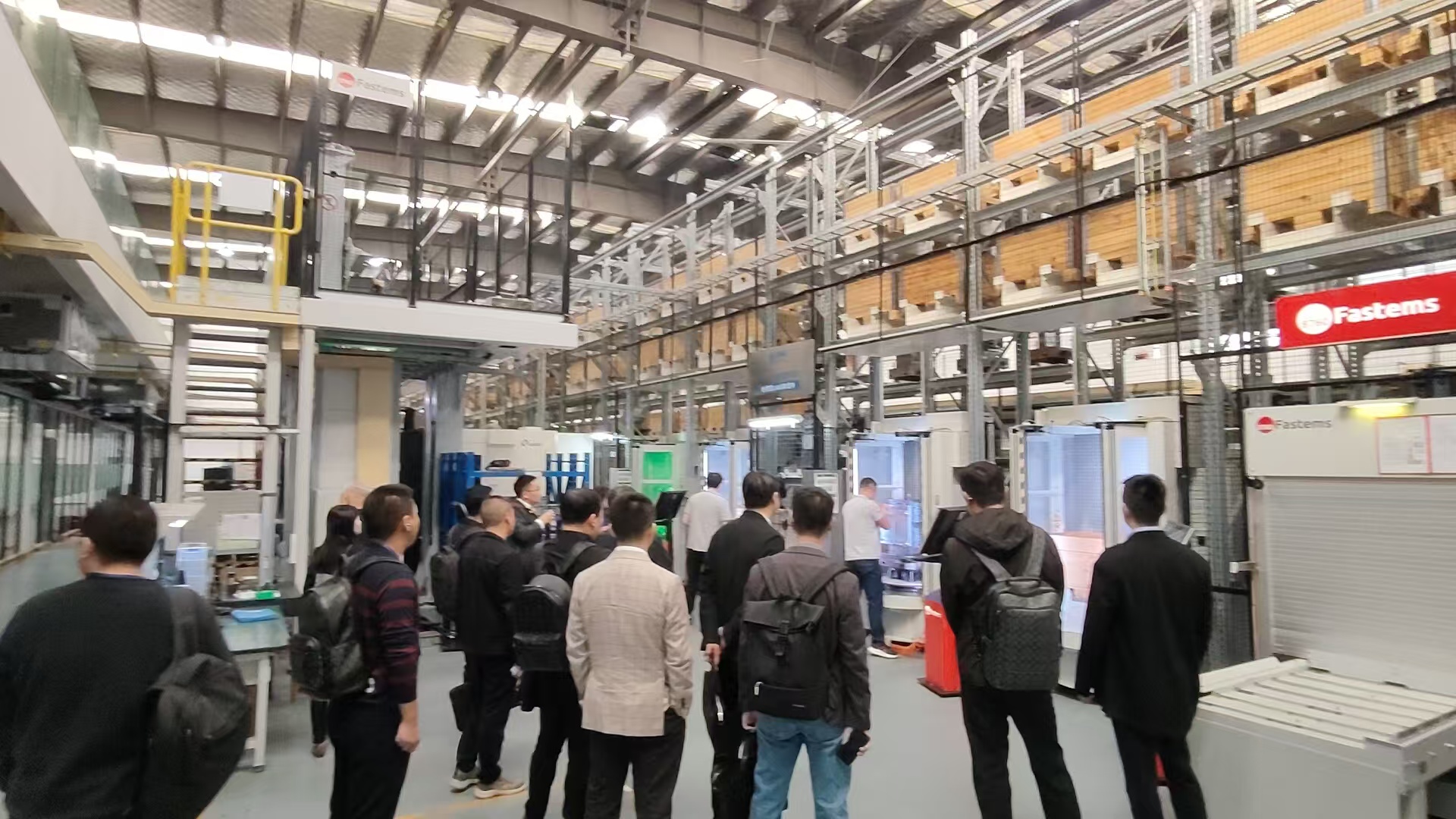

Fastems demonstrated its advanced Manufacturing Management System (MMS), explaining how it maximizes machine utilization through efficient management processes, automated data tracking, and flexible production scheduling. The entrepreneurs also discovered that MMS software, continuously developed for over 40 years, not only balances machine workloads but also monitors equipment status in real-time, providing early warnings to ensure smooth production operations.

Following the tour, a more in-depth session was held in New Hongji’s training room, where the Fastems team elaborated on the core advantages of their automated production line products and the company's philosophy, showcasing how automated production has brought about efficient and intelligent manufacturing. Mr. Li Jian, General Manager of New Hongji, shared his operational experiences with the FMS flexible automated line, recalling how the company personally traveled abroad to evaluate and ultimately choose Fastems products. Mr. Li emphasized that the flexible production line has not only enhanced production agility but also effectively addressed critical issues in production, such as tool management and equipment utilization.

The tour featured rich content, highlighting Fastems’ solutions that enhance production efficiency through innovative technologies like the central tool storage system and pallet automation. With these systems, tools can be transferred between machines, reducing procurement investment and further optimizing machine operations. Additionally, Fastems’ system schedules machine tools in real-time based on current orders, improving equipment utilization and minimizing downtime.

At the end of the event, the entrepreneurs expressed that the visit not only broadened their horizons but also deepened their understanding of intelligent and digital production lines. Looking ahead, New Hongji will continue to collaborate with Fastems to provide more efficient and intelligent production solutions, contributing to the industry’s automation transformation.